Solder Fume Extraction and Filtration Systems for Professional Workstations

Effective protection against solder fumes – powerful, low-maintenance systems for industry and electronics production.

Request a consultation nowEfficient solder fume extraction for clean and safe working environments

Soldering produces harmful vapours, particles and gases - especially from fluxes such as rosin. These can irritate the eyes and respiratory tract, trigger allergic reactions and lead to long-term illnesses. A powerful solder fume extraction system is therefore essential to ensure a safe, clean and legally compliant working environment.

Our extraction systems for soldering fumes capture emissions directly at the source and reliably filter them out of the air using multi-stage systems consisting of pre-filters, fine dust filters and activated carbon filters. Depending on the application, mobile solutions for changing workplaces or stationary systems for fixed soldering lines are available.

Employers are obliged to take suitable protective measures as part of the risk assessment in accordance with Section 6 of the Hazardous Substances Ordinance (GefStoffV) as soon as hazardous substances are present. Our devices help to comply with occupational exposure limits (OELs), protect employee health and avoid production downtimes.

TEKA solder fume extractors stand for low-maintenance operation, durable components and uncompromising quality - developed and manufactured in Germany.

for smooth operation and reduced operating costs

compliant with current norms and safety standards

personal & solution-oriented advice

made for industry and skilled trades

-

Products

- Processes

- Replacement filter

- Mobile extraction and filter systems

- Stationary extraction and filter systems

- Large clean air systems

- Fire protection

- Suction arms and cranes

- Welding and grinding tables

- Suction tables for under-suction / hand plasma applications / flame cutting systems

- Alsident - Acquisition systems for the electronics industry and laboratories

- Fans, pipework and silencers, hoses

- Controls

- Sensors

- Spare parts / accessories

- VIROLINE

- TEKA Service

- Request replacement filter

- Cutting systems

- Company

Built for Industry & Craft

- ✓ Durable quality for continuous use

- ✓ Engineered in Germany – manufactured in DE & EU

- ✓ Maximum air purity standards

- ✓ Personal expert advice included

Matching Replacement Filters

Original filters for maximum performance and long service life – perfectly matched to your TEKA system.

Order replacement filters now

Order replacement filters now

TEKA Product Catalogs

All solutions at a glance: Browse our catalogs online or download selected PDF files.

View catalogs

View catalogs

openning DN200mm

3 black joints, reach 945 mm, table mounted

round, diam. 385 mm, colour white

black, reach 600 mm, table mounted

supplied lenght 1.25 m, extends to 5 m, diam.160mm

reach 600 mm, table mounted

3 white joints; reach: 1185 mm, table mounted

Reach: 765 mm, for table mounting

3 black joints, reach: 750 mm

Automotive, mechanical engineering, chemical industry – TEKA systems are used daily across a wide range of industries

Our extraction and air purification solutions meet the highest standards for occupational safety, efficiency and environmental responsibility. Numerous renowned companies – from mid-sized firms to global technology leaders – rely on our experience and quality.

Last viewed

Efficient solder fume extraction for safe and clean workplaces

Soft soldering produces harmful vapours, particles and gases - especially from fluxes containing rosin. Our solder fume extraction systems ensure reliable capture of these emissions directly at the source and enable a safe, productive and standard-compliant working environment.

Your benefits at a glance:

-

Efficient separation of pollutants: Removal of even fine smoke particles thanks to multi-stage filter technology with pre-filters, fine dust filters and activated carbon filters

-

Healthy working environment: Protection of employees from irritating or allergenic substances such as formaldehyde, isopropanol or colophony residues

-

Low-maintenance and durable: Robust design, tool-free filter change, optionally with digital monitoring

-

Legally compliant operation: Support in complying with occupational exposure limit values (OEL) and measures from the risk assessment in accordance with Section 6 GefStoffV

Manual soldering, repair soldering stations or series production: Our extraction systems can be flexibly adapted to your work processes and workplace requirements - mobile or stationary.

Soldering fumes at the soldering workplace - clean air at the workplace

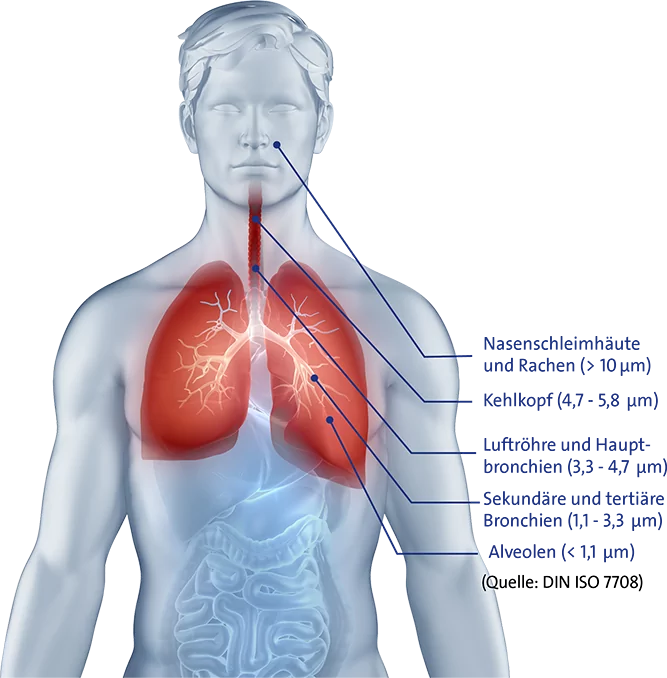

Soldering produces fine particles and vapours that can penetrate deep into the respiratory tract - with risks to health, concentration and long-term performance. Our solder fume extractors capture the emissions directly at the source and reliably filter them out of the air using modern multi-stage technology.

This not only ensures a healthier working environment, but also fulfils all requirements from the risk assessment (§6 GefStoffV) and contributes to compliance with the workplace limit values (AGW).

Your benefits:

-

Healthy employees: Reduction of harmful substances such as formaldehyde or colophony smoke

-

Less downtime: Less absence due to illness thanks to clean air

-

Safe processes: Reliable filtration and long-term stable working conditions

Our extraction units are suitable for all soldering workstations - from ESD tables to automated series production.

Why TEKA? - Solder fume extraction systems that set standards

TEKA has been developing and manufacturing extraction technology for demanding applications in industry and trade for over 30 years. Our soldering fume extraction systems combine technological innovation with practical functionality - consistently focussed on the needs of professional workplaces.

That speaks for TEKA:

-

Made in Germany: Development and production in Germany - for maximum reliability and durability

-

State-of-the-art filter technology: Combined pre-filter, fine dust and activated carbon filter solutions for safe air quality

-

Flexible systems: Mobile, stationary and integrable solutions for individual workstations through to automated production lines

-

Cross-industry experience: Customers from electronics manufacturing, the automotive industry, medical technology, laboratory and training environments

-

Service-orientation: Short delivery times, expert advice and comprehensive technical support

-

Sustainability: Resource-optimised production and durable components reduce operating costs and environmental impact

Take advantage of our experience and let us advise you individually - we will develop the right solution for your soldering application.

Looking for a custom extraction solution? We’re here to help.

Whether it's a welding workplace, production hall or special application - we can help you choose the right extraction system.

Use the enquiry form and our team will get back to you as quickly as possible with a customised recommendation.

FAQ – Your Questions About Solder Fume Extraction

Why is solder fume extraction necessary?

Soldering generates harmful fumes and particles, especially from fluxes such as rosin. Without proper extraction, these substances enter the breathing air and can cause long-term health issues. A professional extraction system provides effective protection and ensures compliance with legal requirements.

What types of extraction systems are suitable for soldering?

Options include mobile tabletop extractors, stationary units, or centrally managed systems. Key factors include the workstation type, air volume, filtration requirements, and desired level of automation.

How do I find the right extraction system for my production?

Important factors include the number of workstations, soldering processes used, type of flux, and room layout. Our experts will help you select the right system – from single-station units to series production solutions.

What regulations apply to solder fume extraction?

According to Section 6 of the German Hazardous Substances Ordinance (GefStoffV), employers are required to assess and reduce airborne hazardous substances. Occupational exposure limits (AGW) must also be observed – for example, for formaldehyde or isopropanol.

How often do filters need to be replaced?

This depends on usage, contamination levels, and the filter system. TEKA recommends regular visual checks and adherence to manufacturer guidelines. Many units are equipped with digital filter status indicators.

Are mobile solder fume extractors available?

Yes, mobile tabletop units are ideal for individual workstations, changing locations, or temporary use. They are easy to integrate and highly flexible.

What types of filters are used in solder fume extraction systems?

Multi-stage filter combinations are typically used: pre-filters for coarse particles, fine dust filters (e.g. HEPA H13/H14), and activated carbon filters for gas adsorption. The configuration depends on the type of contaminants and workplace requirements.

Can existing soldering workstations be retrofitted?

Yes. Many TEKA systems are modular and can be easily integrated into existing workstations or production lines – even during ongoing operations.

Are there funding opportunities for solder fume extraction systems?

Depending on industry, region, or project scope, funding may be available through programs such as BAFA, BG ETEM, or regional initiatives. We’ll gladly support you with research and application.

Does TEKA offer leasing or rental options?

TEKA primarily sells systems directly. However, rental or leasing models can be arranged individually – for testing, interim use, or temporary projects. Please contact us for details.