Ackermann Verkehrstechnik

"When equipping workstations in the new hall, we wanted to invest in really good extraction technology - and we were not disappointed. -Heinz Kölking, master craftsman

The Ackermann company, founded in 1947, which manufactures a wide variety of traffic engineering products with around 50 employees at two locations in Borken, Westphalia, required extraction systems for several work areas in the company. Special care had to be taken in one area where aluminum and galvanized structural steel are ground. Special protective measures are required when processing aluminium, especially when other processes are used in the immediate vicinity. This is because inhaling the aluminium-containing dusts released can lead to serious illnesses in the long term. In addition, aluminum dust in combination with air and a source of ignition poses a fire and explosion hazard and represents a considerable safety risk for employees.

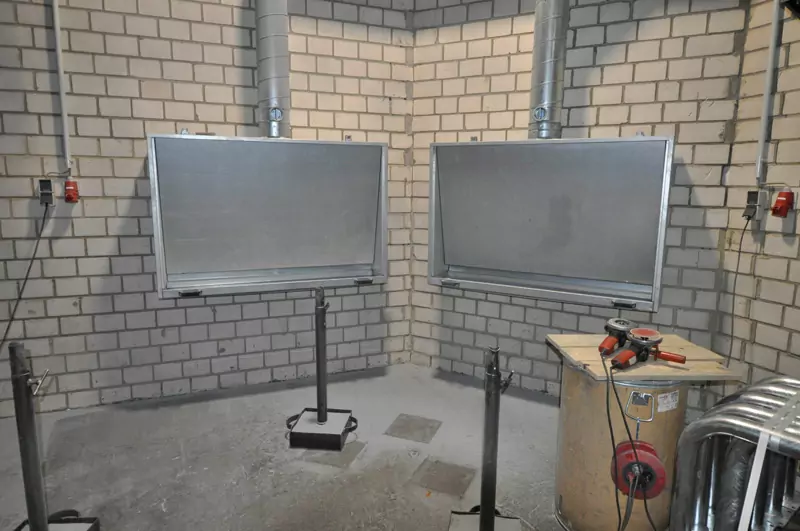

In order to capture the high amount of dust in this area as completely as possible and to remove it without risk, Ackermann uses a so-called dry process with wet separation in a wet separator. When grinding aluminium, the dust mixture produced is extracted directly via pipes connected to the belt grinders. When processing structural steels, it is collected via several swirl extraction walls. Afterwards the contaminated air is led to the whirl wet separator of TEKA type WNA-7500-AL and separated there. In order to prevent explosion hazards due to the simultaneous processing of structural steel in the immediate vicinity, the released dust is led to the wet whirl separator via separate pipes in accordance with TRGS 109 and only comes together in the wetting area of the plant. The contaminated air is cleaned by swirling the dust with water. The dust particles present in the air stream are enclosed and bound with water. The separated dust particles settle as sludge in the lower water box and can be drained through the ball valve installed at the lowest point of the unit and removed through a maintenance flap. The ventilator is suitable for continuous operation and is mounted on the unit as standard.

The advantages at a glance: Vortex wet separator AL

Plant with elaborated explosion protection concept

Simple and trouble-free operation without pumps or nozzles that can lead to malfunctions

Interior of the WNA-AL protected against sparks by explosion-proof motor and grounded built-in parts

Further information:

Information at Tel. +49(0)2541-84841-0 or by e-mail at info@teka.eu