Welding Fume Extraction for Air Quality and Safety in Welding

Our systems protect people and machines – directly at the source. Efficient, durable and tailored to your industry.

Request consultationWelding fume extraction for a clean and safe working environment

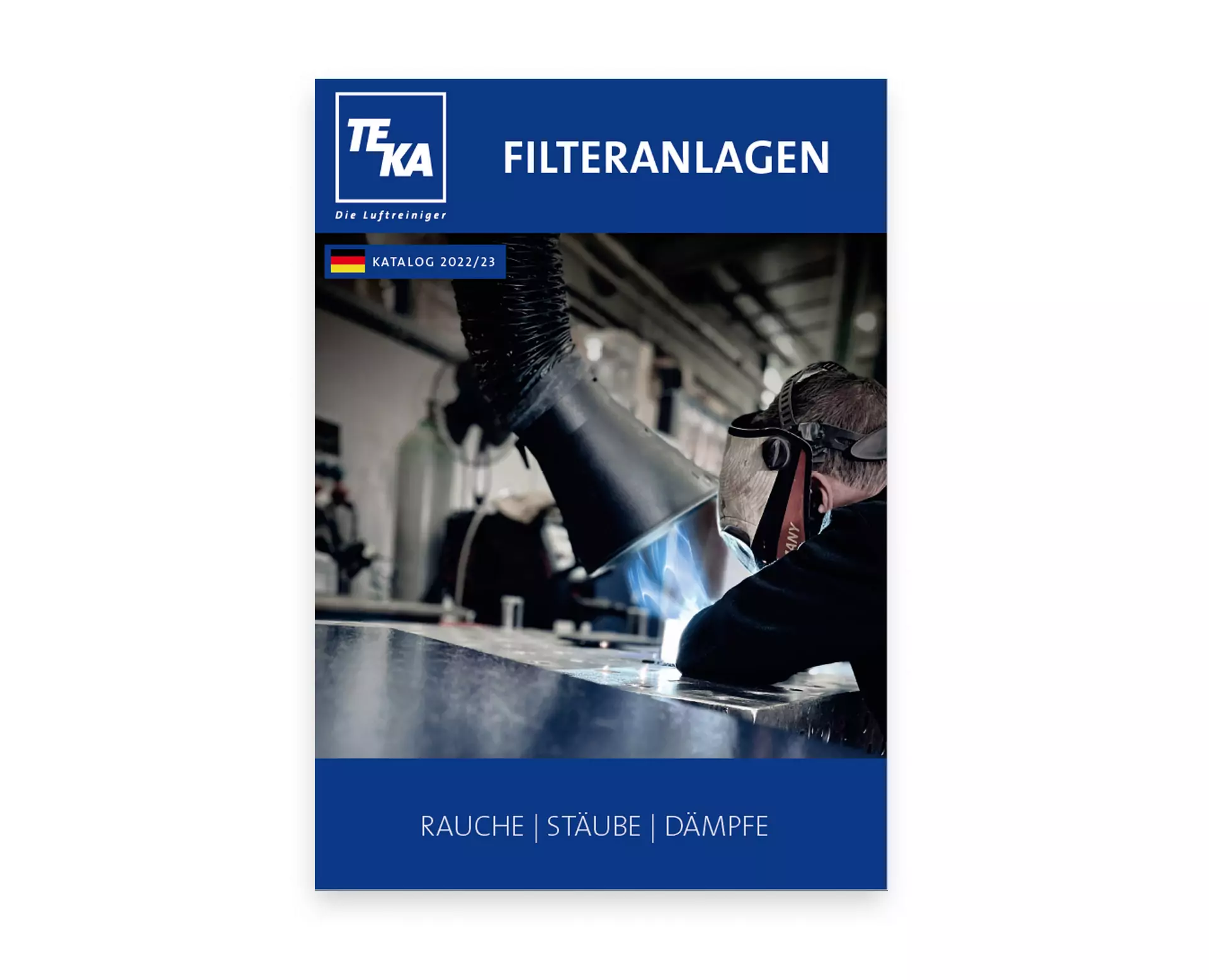

Welding produces emissions that are harmful to health - including fine dust, heavy metals and toxic gases. When inhaled, these particles penetrate deep into the lungs and can lead to serious illnesses such as bronchitis, asthma, cardiovascular problems and even cancer. But it's not just your health that is affected: Your product quality also suffers when welding fumes build up on workpieces and lead to corrosion or contamination.

Professional extraction systems are therefore essential for all companies that prioritise occupational safety, efficiency and sustainable production. A suitable extraction unit - for example with a flexible extraction arm or integrated torch extraction - captures the fumes directly at the point of origin. Welding fume filters reliably clean the air before it returns to the work area. The result: a clean, safe environment in which your employees can concentrate and work productively.

for smooth operation and reduced operating costs

compliant with current norms and safety standards

personal & solution-oriented advice

made for industry and skilled trades

-

Products

- Processes

- Replacement filter

- Mobile extraction and filter systems

- Stationary extraction and filter systems

- Large clean air systems

- Fire protection

- Suction arms and cranes

- Welding and grinding tables

- Suction tables for under-suction / hand plasma applications / flame cutting systems

- Alsident - Acquisition systems for the electronics industry and laboratories

- Fans, pipework and silencers, hoses

- Controls

- Sensors

- Spare parts / accessories

- VIROLINE

- TEKA Service

- Request replacement filter

- Cutting systems

- Company

Built for Industry & Craft

- ✓ Durable quality for continuous use

- ✓ Engineered in Germany – manufactured in DE & EU

- ✓ Maximum air purity standards

- ✓ Personal expert advice included

Matching Replacement Filters

Original filters for maximum performance and long service life – perfectly matched to your TEKA system.

Order replacement filters now

Order replacement filters now

TEKA Product Catalogs

All solutions at a glance: Browse our catalogs online or download selected PDF files.

View catalogs

View catalogs

angular 300 x 360 mm, PVC, black

for mobile/stationary filter units

600x635x800mm (WxDxH)

Hose type, internal joints

internal joints, 1,20 - 2,06 m incl. accessories

Motor 0,75 KW, 400 V/50Hz

Hose type, internal joints

internal joints, working length 1,20 - 2,06 m

2000 m³/h, 0,75 kW, 400V/50Hz

1,1 kW, 230V/50Hz, incl. 3m suction arm

with suction arm 3 m, hose type, internal joints

Automotive, mechanical engineering, chemical industry – TEKA systems are used daily across a wide range of industries

Our extraction and air purification solutions meet the highest standards for occupational safety, efficiency and environmental responsibility. Numerous renowned companies – from mid-sized firms to global technology leaders – rely on our experience and quality.

Last viewed

Welding fume extraction: Your filter for a clean and safe working environment

Welding produces emissions that are harmful to health - including fine dust, heavy metals and toxic gases. When inhaled, these particles penetrate deep into the lungs and can lead to serious illnesses such as bronchitis, asthma, cardiovascular problems and even cancer. But it's not just your health that is affected: Your product quality also suffers when welding fumes build up on workpieces and lead to corrosion or contamination.

Professional extraction systems are therefore essential for all companies that prioritise occupational safety, efficiency and sustainable production. Flexible extraction arms - ideally directly on the welding torch or via an extraction bonnet - capture the fumes directly at the source. Welding fume filters reliably clean the air before it returns to the work area. The result: a clean, safe environment in which your employees can concentrate and work productively.

Welding fume extraction: Your filter for a clean and safe working environment

Welding produces harmful emissions - including fine dust, heavy metals and toxic gases. When inhaled, these particles penetrate deep into the lungs and can lead to serious illnesses such as bronchitis, asthma, cardiovascular problems and even cancer. But it's not just your health that is affected: Your product quality also suffers when welding fumes build up on workpieces and lead to corrosion or contamination.

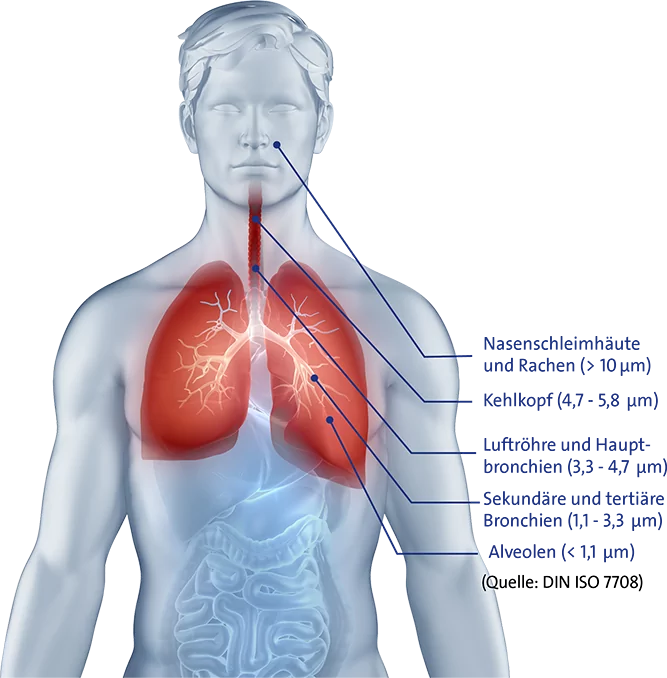

The invisible danger: welding fumes and their effects

Welding fumes consist of a mixture of ultra-fine particles and gaseous pollutants that are released during welding. The smaller the particles, the deeper they can penetrate into the respiratory tract - right into the alveoli. There they trigger inflammation and can cause serious illnesses in the long term.

Typical health consequences are:

- Respiratory diseases: Bronchitis, Asthma, Lung cancer

- Cardiovascular diseases: Heart attack, Stroke

- Nerve damage: Headaches, Dizziness, Concentration problems

- Skin irritation and allergies

Ultra-fine particles below 1 µm are particularly critical:

- > 10 µm: are usually caught in the nose and throat

- 4.7 - 5.8 µm: reach the larynx

- 3.3 - 4.7 µm: enter the trachea and bronchi

- 1.1 - 3.3 µm: penetrate deeper into the lower bronchi

- < 1.1 µm: reach the alveoli - where long-term damage is difficult to recognise

In addition to the health risks, welding fumes also have a negative impact on workpieces and surfaces. Corrosion, contamination and increased rejects are the result - especially with sensitive materials or high-quality weld seams.

Effective extraction: protection for man and machine during welding

A professional fume extraction system removes pollutants directly at the source - before they can spread throughout the working environment. Especially during welding work, reliable welding fume extraction is crucial for health and safety at work. Flexible extraction arms or integrated torch extraction systems ensure that smoke, fine dust and gases are captured immediately. This not only protects the health of your employees, but also the direct breathing zone for the welder at the workplace.

Modern extraction systems offer numerous advantages:

-

High extraction performance: Reliable capture even for large-scale or intensive welding processes

-

Flexibility: Use of mobile or stationary systems - customised to your workplace

-

User-friendliness: Simple operation, quick installation and low-maintenance technology

-

Industrial suitability: Robust design for continuous use in demanding production environments

Welding and cutting: Extraction units and filter systems for clean air

Efficient welding fume extraction is based on two central components: Extraction units to capture the pollutants and filter systems to clean the air. Both systems work together to protect employees from hazardous exposure and reliably fulfil legal requirements.

Efficient welding fume capture is only possible if extraction units capture the fumes directly at the source - for example with extraction arms or bonnets. This prevents harmful particles from spreading into the room air in the first place.

Filter systems filter the finest pollutants from the welding fumes before the air is returned to the work area. Depending on the application, different filter devices are used - e.g. HEPA systems, activated carbon modules or electrostatic filters.

Several factors are decisive when selecting the right system:

-

Type and intensity of the welding process

-

Number of workstations or simultaneous work processes

-

Space conditions on site

-

Compliance with legal requirements (e.g. TRGS 528, DGUV regulation 109-002)

TEKA offers tested and certified systems that fulfil these requirements - in mobile, stationary and modular versions.

Looking for a custom extraction solution? We’re here to help.

Whether it's a welding workplace, production hall or special application - we can help you choose the right extraction system.

Use the enquiry form and our team will get back to you as quickly as possible with a customised recommendation.

FAQ – Your Questions About Welding Fume Extraction

Why is welding fume extraction so important?

Welding produces harmful gases, fumes, and ultrafine particles that are hazardous to health. Without extraction, they contaminate the breathing air and endanger the long-term health of your employees. Professional extraction ensures occupational safety and a clean production environment.

What types of welding fume extraction systems are available?

Options include mobile extraction units, extraction arms, stationary filter units, and central hall extraction systems. The right solution depends on your working environment, welding processes, and emission levels.

How do I find the right extraction system for my company?

The choice depends on factors such as workstation size, number of welding stations, processes used, and flexibility requirements. Our experts will help you find the ideal solution for your needs.

What legal regulations apply to welding fume extraction?

In Germany, regulations such as TRGS 528 and the Workplace Ordinance apply. These require hazardous substances to be captured as directly as possible at the source. IFA and W3 certifications are also important for safe operation of certain systems.

How often does a welding fume extractor need maintenance?

Maintenance intervals depend on usage. In general, filters should be checked and replaced regularly to ensure performance and protection. Many devices display maintenance requirements digitally.

What filter classes are used in welding fume systems?

Depending on the application, welding fume filters comply with DIN EN ISO 16890 or are IFA W3 certified for stainless steel welding. TEKA uses powerful multi-stage filters that reliably capture hazardous particles.

How loud are welding fume extraction systems?

Modern units operate between 60 and 75 dB(A), comparable to a conversation or vacuum cleaner. Extra-quiet models are suitable for noise-sensitive areas or training rooms. Mobile devices are generally louder than central systems.

Can an extraction system be retrofitted?

Yes, many TEKA systems are modular and can be integrated into existing workstations later on.

Are there funding options for purchasing a system?

Depending on your industry and location, various funding programs are available – for example through BAFA, BG BAU, or regional initiatives. We are happy to advise you on applications and eligible equipment.

Is renting or leasing an extraction system possible at TEKA?

TEKA sells its extraction systems primarily through direct sales. However, for special applications, such as temporary projects, test applications or as an interim solution, individual rental or leasing agreements can also be realized on request. Please do not hesitate to contact us.