AirCut plasma cutting systems from TEKA celebrate their premiere at EuroBLECH 2024

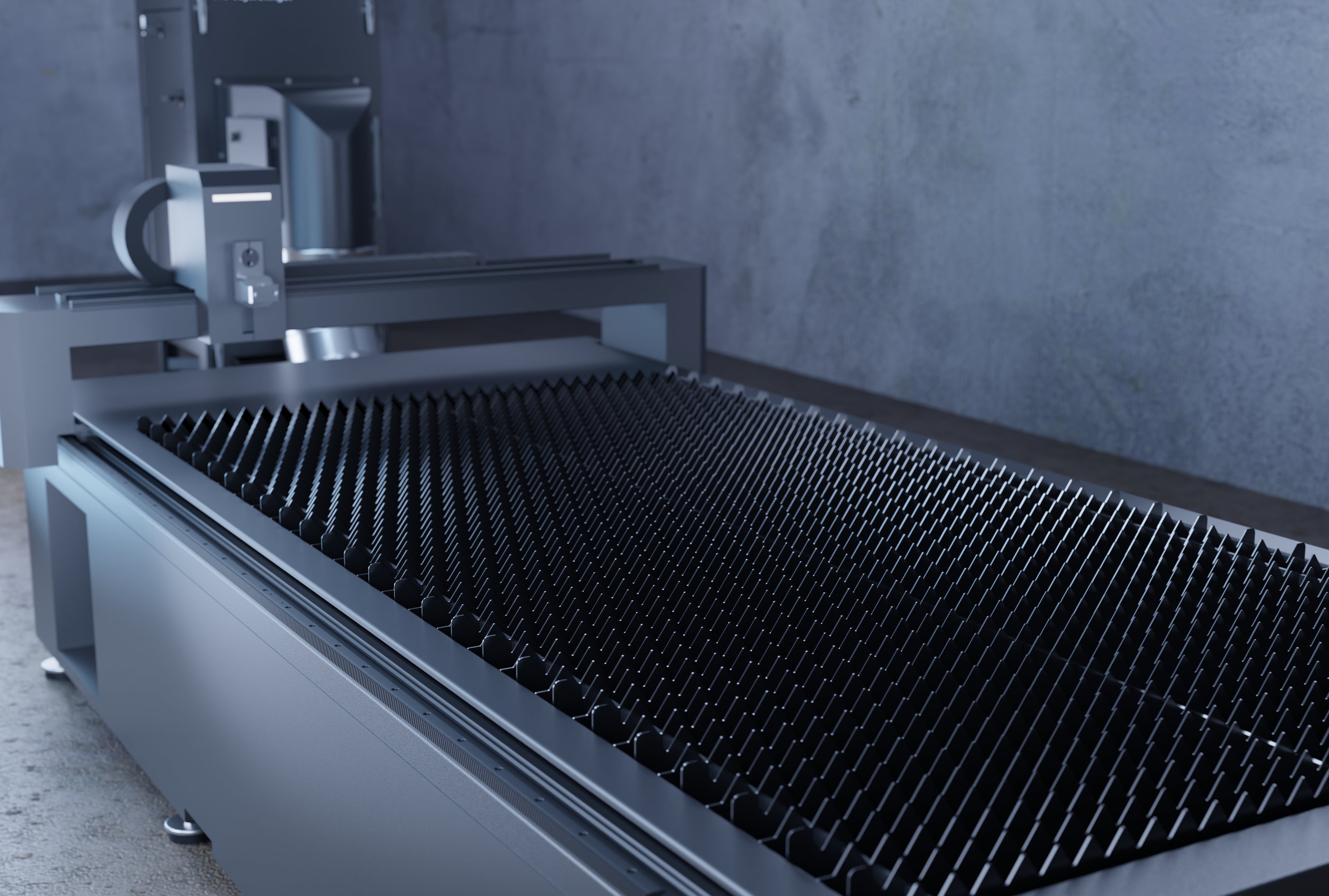

Coesfeld, 05 September 2024 +++ TEKA Absaug- und Entsorgungstechnologie GmbH, headquartered in Coesfeld (www.teka.eu), will be presenting a product premiere at EuroBLECH in Hanover (22-25 October 2024, stand 13-F58). A complete plasma cutting system from TEKA will be on show for the first time at the trade fair. The new "AirCut" series from TEKA is an integral solution in which all components are harmonised with one another: Plasma cutting head, flame cutting table, EcoCube filter system, CAD/CAM software, component library and Industry 4.0 connection. One advantage of the new complete solution is that it can be installed ready for cutting within one day according to the plug & play principle. The new AirCut plasma cutting systems are aimed in particular at the needs of small and medium-sized metalworking companies. They combine precision, robustness, user-friendliness and moderate costs. TEKA offers the new AirCut plasma cutting systems via various sales channels.

AirCut plasma cutting systems in two sizes

The new plasma cutting systems from TEKA are available in two sizes at launch: as AirCut medium format with an effective cutting area of 1250 mm x 2500 mm and as AirCut large format with a cutting area of 1520 mm x 3060 mm. What both AirCut variants have in common is that they consist of perfectly harmonised components. They impress with their quality and user-friendliness – at an attractive price point. With a maximum positioning speed of up to 40,000 mm/min and a positioning accuracy of ≤ 0.15 mm/m, the AirCut plasma cutting systems are also extremely precise.

Robust and future-proof with CAD/CAM control and Industry 4.0 networking

When developing AirCut, TEKA placed great emphasis on durability. A flame-cutting table made of welded structural steel ensures maximum stability, and the precise rack and pinion drive for the X and Y axes of the guide machine is a design element that guarantees not only high accuracy but also durability. Ease of operation and user-friendliness were also mong the key requirements for the TEKA developers. A free-standing operating terminal with Intel Core i5 processor and 19-inch screen is included as part of the AirCut systems. The CAD/CAM software supplied, including a component library, makes it extremely easy to control the cutting processes. A Panasonic FB-I4C InfoHub module with cloud access and networking options via M2M communication protocols such as OPC UA and MQTT ensure Industry 4.0 connectivity and long-term viability.

With the proven TEKA EcoCube filter system

To ensure a clean working environment, TEKA has equipped the automatic extraction table with sectional control. An integrated interface allows for remote start and power supply of the filter system. For the AirCut series, the developers have chosen the proven and W3-certified EcoCube filter system, one of the bestsellers in the TEKA portfolio. The EcoCube filter systems also follow the plug-and-play principle. They can be installed and ready for operation on-site in less than half an hour. In the AirCut series, the EcoCube filter systems are available in two performance levels: EcoCube 5.5 kW (medium format) and EcoCube 7.5 kW (large format). Thanks to a frequency inverter, all EcoCube filter systems operate particularly efficiently - they actively adjust the required suction power during the cutting process.

About TEKA

TEKA Absaug- und Entsorgungstechnologie GmbH (www.teka.eu) has been one of Europe's leading manufacturers of extraction and filter systems for industry, commerce, trade, and laboratories for 25 years. As a reliable partner and expert in clean air in the workplace, TEKA supplies medium-sized companies and corporations from the metalworking industry, the electrical industry, and laboratory technology. TEKA filter systems create clean air for employees at industrial workplaces throughout Europe and contribute to environmental protection. The TEKA product portfolio ranges from mobile and stationary systems for point extraction to ventilation solutions for hall air filtration and complex system solutions for the cutting industry. This portfolio is complemented by cutting, welding, and flame-cutting tables as well as visual and sound insulation. Since 2024, TEKA has also been offering complete plasma cutting systems with its new AirCut series, which impress with their efficiency, quality, and user-friendliness.

At the TEKA sites in Coesfeld and Weseke in North Rhine-Westphalia, around 150 employees work in development, production, and sales to offer customised solutions with intensive consulting, service, and assembly services, internationally as well. In the industry, TEKA is recognised as a problem solver that responds intensively to the needs of trade partners and end customers. Almost all TEKA products fulfil the safety requirements for the highest welding fume separation class and have been awarded the W3 quality certificate in accordance with DIN EN ISO 15012-1. TEKA is also active in the field of Industry 4.0, as demonstrated by the Airtracker family for digital room air monitoring and the SmartFit boxes for system networking. TEKA is actively involved in the Industry Business Network 4.0 (IBN 4.0) association and is committed to the development of system standards.