Product number:

9501420015015300

IFA-AUDITED

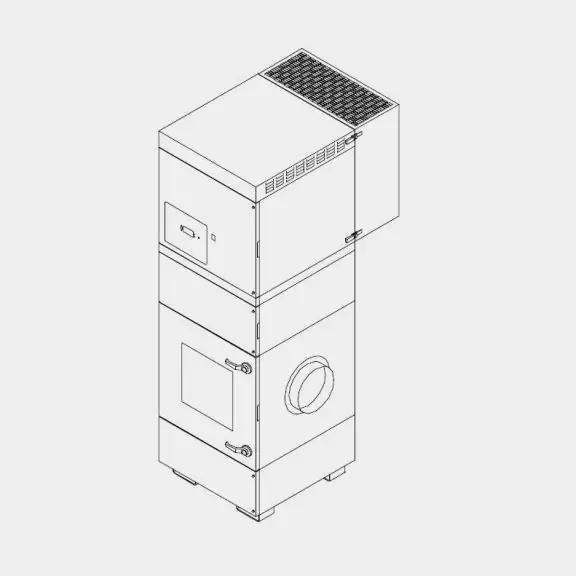

FilterCube 2N, 1,5 kW, 15,6 m²

Delivery time on request

You will see your price after login

FilterCube 2N, 1,5 kW, 15,6 m²

The FilterCube 2N stationary filter unit is an IFA-tested filter system that takes up very little

space and can be used for an extremely wide range of applications, primarily in the metalworking

sector.

Filtration performance of over 99 % ensures that fumes and dusts are reliably separated out.

The filter cartridges are cleaned by means of compressed air, meaning that it is not necessary to

replace the filters until the through-flow of air is no longer sufficient.

The dust can be removed from the collecting tray very easily. This reduces downtimes to a

minimum. The clean air can usually be fed back into the workplace, meaning that during periods

in which heating is required, in particular, no new hot air has to be fed into the premises. In this

way, the FilterCube helps reduce energy costs.

Standard equipment

- Two standard filter cartridges, with filter surface area depending on air flow rate

- Display-controlled filter cleaning

- Fan control

Possible options

- Other grades of filter cartridge, with filter surface area depending on air flow rate

- Safety upgrade (particle sensor, compressed air shut-off valve, maintenance door with

inspection window for FilterCube 2N with connecting device for CO² fire extinguisher

Possibility of combined use with other TEKA products

- Collecting devices such as suction arms, cranes or suction tables

- Spark separator

- Automatic dosing device for precoating

space and can be used for an extremely wide range of applications, primarily in the metalworking

sector.

Filtration performance of over 99 % ensures that fumes and dusts are reliably separated out.

The filter cartridges are cleaned by means of compressed air, meaning that it is not necessary to

replace the filters until the through-flow of air is no longer sufficient.

The dust can be removed from the collecting tray very easily. This reduces downtimes to a

minimum. The clean air can usually be fed back into the workplace, meaning that during periods

in which heating is required, in particular, no new hot air has to be fed into the premises. In this

way, the FilterCube helps reduce energy costs.

Standard equipment

- Two standard filter cartridges, with filter surface area depending on air flow rate

- Display-controlled filter cleaning

- Fan control

Possible options

- Other grades of filter cartridge, with filter surface area depending on air flow rate

- Safety upgrade (particle sensor, compressed air shut-off valve, maintenance door with

inspection window for FilterCube 2N with connecting device for CO² fire extinguisher

Possibility of combined use with other TEKA products

- Collecting devices such as suction arms, cranes or suction tables

- Spark separator

- Automatic dosing device for precoating

Properties

| Cleaning pressure (bar): | 2-4 |

|---|---|

| Compressor capacity (litres per minute): | 75 |

| Dust container volume (litres): | 50 |

| Engine control system design: | separat montierbar |

| Fan design: | auf der Anlage im Schalldämmgehäuse |

| Filter control structure: | separat montierbar |

| Intake manifold (mm): | NW 160 – (Seite wahlweise links oder rechts) |

| fan: | direktgetrieben, wartungsarm |

| medium to be filtered: | trockener, fettfreier bzw. ölfreier Staub / Rauch |

| Volumetric flow (m³/h): | 2.500 |

| max. pressure (Pa): | 2.900 |

| Operating point: | 1.480 m³/h bei 2.500 Pa |

| Engine power (kW): | 1,5 |

| Supply voltage (V): | 400 |

| Connection frequency (Hz): | 50 |

| Current consumption (A): | 3,5 |

| Current type: | 3Ph+N+PE |

| Automatic cleaning: | Ja |

| Filter control: | automatische Filterabreinigung, Siemens S7 |

| Engine control: | Motorschutzschalter |

| Vorfilter: | inkl. |

| main filter: | Staubklasse nach DIN EN 60335-2-69:2008 |

| Cartridges number: | 2 à 7,8 |

| Filter surface (m²): | 15,6 |

| Ausblas: | über Schalldämm Modul nach oben |

| Sound level (dB(A)): | < 68 |

| Width (mm): | 665 |

| Depth (mm): | 983 |

| Height (mm): | 2.070 |