TEKA – The Air Cleaners

We understand the demands of manufacturing – and develop solutions that work.

Request consultation now

Notice for existing customers:

For existing business customers, we provide a

personal shop login at contact person level

for the clear management of orders, order history and

account-related information.

Access is activated after internal review by

TEKA.

Request your login here

-

Products

- Processes

- Replacement filter

- Mobile extraction and filter systems

- Stationary extraction and filter systems

- Large clean air systems

- Fire protection

- Suction arms and cranes

- Welding and grinding tables

- Suction tables for under-suction / hand plasma applications / flame cutting systems

- Alsident - Acquisition systems for the electronics industry and laboratories

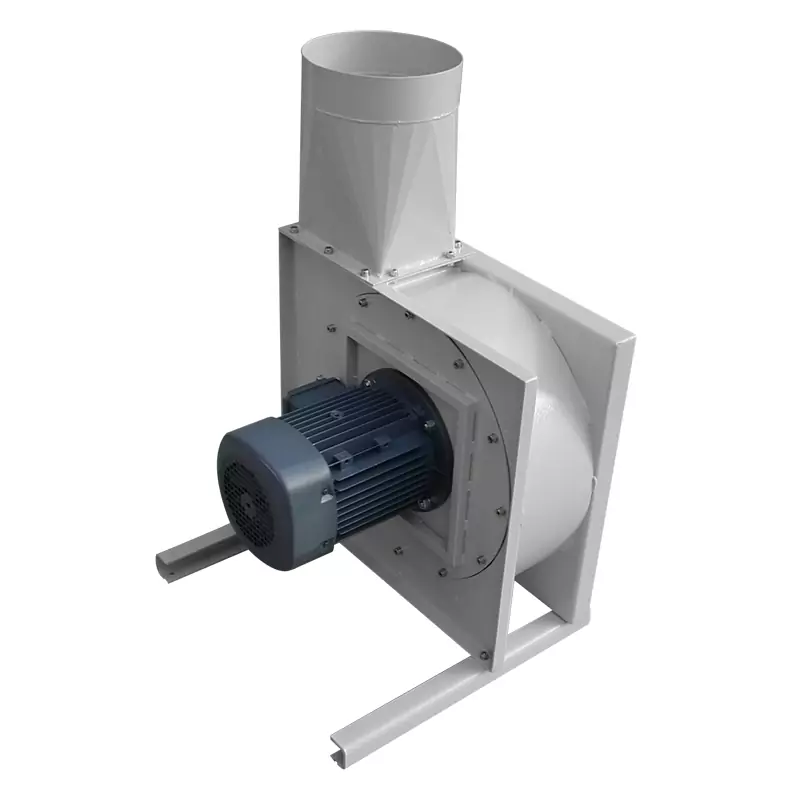

- Fans, pipework and silencers, hoses

- Controls

- Sensors

- Spare parts / accessories

- VIROLINE

- TEKA Service

- Request replacement filter

- Cutting systems

- Company

Built for Industry & Craft

- ✓ Durable quality for continuous use

- ✓ Engineered in Germany – manufactured in DE & EU

- ✓ Maximum air purity standards

- ✓ Personal expert advice included

Matching Replacement Filters

Original filters for maximum performance and long service life – request a quote directly using the serial number of your system.

Request suitable replacement filters now

Request suitable replacement filters now

TEKA Product Catalogs

All solutions at a glance: Browse our catalogs online or download selected PDF files.

View catalogs

View catalogs

type WNA 9000 AL

(230V, 50-60 Hz)

(230V; 50-60Hz)

2 air inlets diam. 150

(115-230V; 50-60Hz)

(230V; 50-60Hz)

2 x 8m suction arm, hose type, external joints

especially for the stamp production

2000 x 1000 x 850 (1650) mm

Motor 11,0 kW, 400 V/50Hz

4m suction arm with external joints

für effiziente Abläufe und minimalen Stillstand

nach aktuellen Normen & Standards

persönlich & lösungsorientiert

für Industrie & Handwerk gemacht

Automotive, mechanical engineering, chemical industry – TEKA systems are used daily across a wide range of industries

Our extraction and air purification solutions meet the highest standards for occupational safety, efficiency and environmental responsibility. Numerous renowned companies – from mid-sized firms to global technology leaders – rely on our experience and quality.

Zuletzt angesehen

Looking for a custom extraction solution? We’re here to help.

Whether it's a welding workplace, production hall or special application - we can help you choose the right extraction system.

Use the enquiry form and our team will get back to you as quickly as possible with a customised recommendation.