FILTERCASE is worth its weight in gold

May 18, 2022

TEKA | Katrin Herbers

Master goldsmith relies on TEKA extraction for two years now

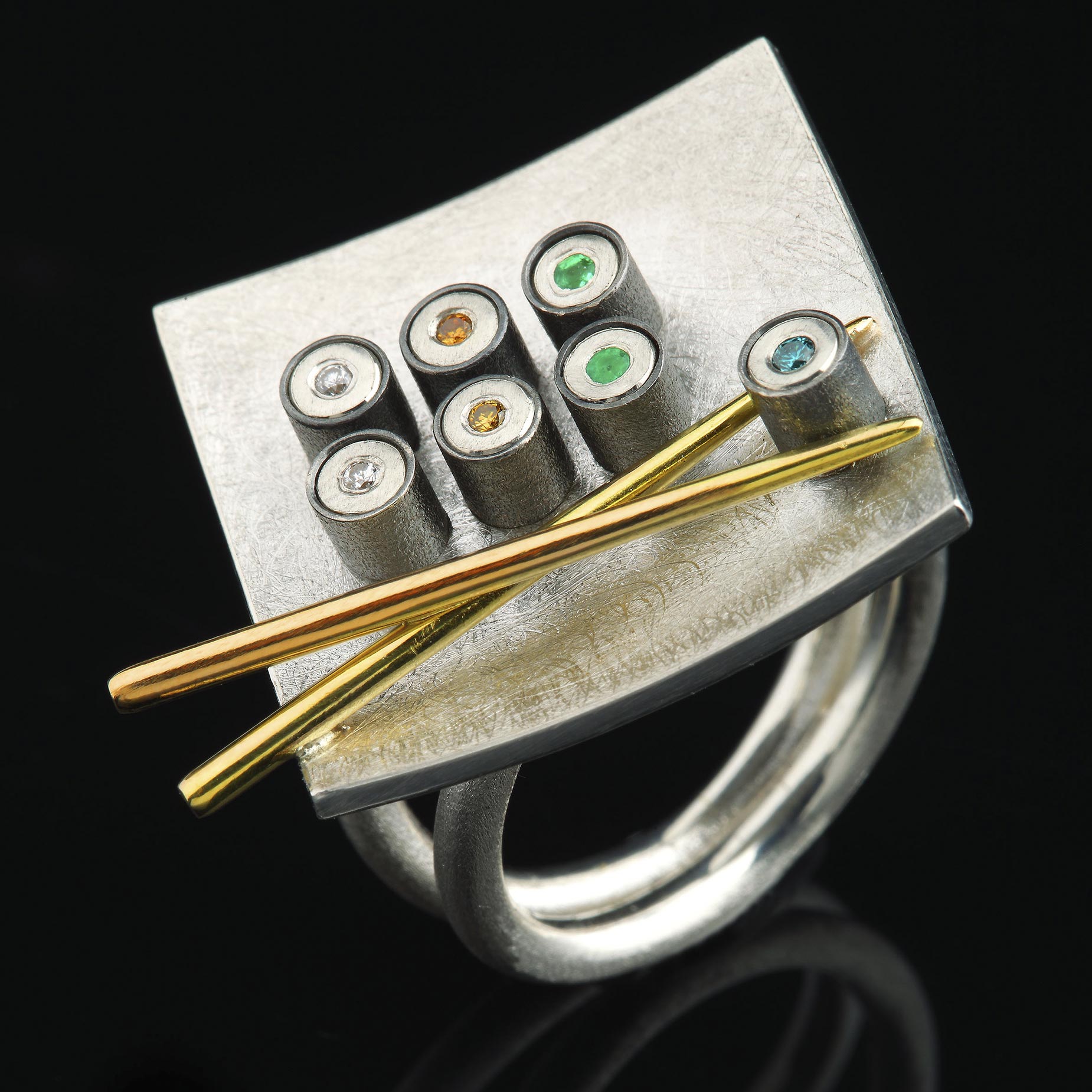

Jochen Zimmer slowly runs the burner over the gold nugget until it is completely liquid. Then the master goldsmith pours the mass into a melting pot. He will need many more hours of work before the old gold is transformed into a new, individually crafted piece of jewellery.

The man from Haßfurt, who has been creating unique pieces from high-quality materials for his jewellery studio for 20 years and with two employees, spends these hours in his workshop. Jochen Zimmer does not have to worry about the harmful vapours, fumes and dusts that are released when melting, soldering, grinding or polishing gold and other precious metals - at least not since he started using the Filtercase SL from TEKA.

Mini unit fits in any workshop

The pollutants produced are removed via an extraction arm made of aluminium tubes. Jochen Zimmer can easily move this arm into any desired position via three joints and bring the pipe nozzle close to the point of discharge - as recommended by the employers' liability insurance association. The filter case SL, which collects and filters the polluted air, is hardly noticeable in the small workshop. It fits on a workshop cupboard due to its small size (280 W x 330 D x 440 H mm) and low weight (15 kg). Another one is located under a work table.

The Filtercase SL is equipped with a multi-stage filter system. A pre-filter mat separates the coarse particles. The air is then passed through a fine dust filter, where even the last fine smoke and dust are separated. An activated carbon filter mat binds gases and unpleasant odours. The filter system is equipped with a powerful high-pressure turbine that can be infinitely adjusted. After filtration, the cleaned air is returned to the workshop via a rear discharge grille. An automatic filter monitoring system shows the user when a filter change is necessary. The change is carried out in a maintenance-friendly manner via the unit's cover, which is secured with tension locks. The unit is immediately ready for use.

Jochen Zimmer is satisfied with the units: "I use them about three hours a day. They work perfectly, are very space-saving and the volume is also okay.

Facts and figures about the Filtercase SL

• Maximal fan performance [m³/h]: 280

• Maximal compression (Pa): 20.000

• Motor performance (kW): 1.1

• Supply voltage (V): 230

• Mains frequency (Hz): 50

• Current consumption (A): 6

• Main filter: Fine dust filter with activated carbon filter mat

•Separation efficiency of the unit (%): > 99

• Intake nozzle (mm): 2 x NW 50 at the rear in the cover (1 x with blind cover)

• Noise level (dB(A)): 65