GPS - Gemeinnütziges Personalservice Kärnten GmbH

"After intensive examination of the offers, we finally decided on what we considered to be TEKA's most mature concept. In addition, the price-performance ratio was the most attractive". - Engineer Gottfried Pototschnig MBA range leader training center Villach

The training center of the Gemeinnützige Personalservice Kärnten GmbH in the Villach Technology Park with an investment sum of 6.5 million euros is considered a showcase project for inter-company apprenticeship training in Austria. The center offers additional training modules for the occupational groups metal technology, mechatronics and electrical engineering in addition to the apprenticeship in companies and vocational schools. For the welding shop with eight manual workstations, a plasma hand cutting table and a sound-insulated grinding chamber, the training center needed a solution that would reliably and space-savingly cleanse different work areas of pollutants.

The Villach Training Center (AV) decided on a stationary extraction and filter system type ZPF 6H with an upstream spark pre-separator: This is a central filter system that is suitable for a variety of extraction problems at several workplaces simultaneously. It removes and filters fumes and dust even when working with unalloyed metals and precious metals as well as galvanized material.

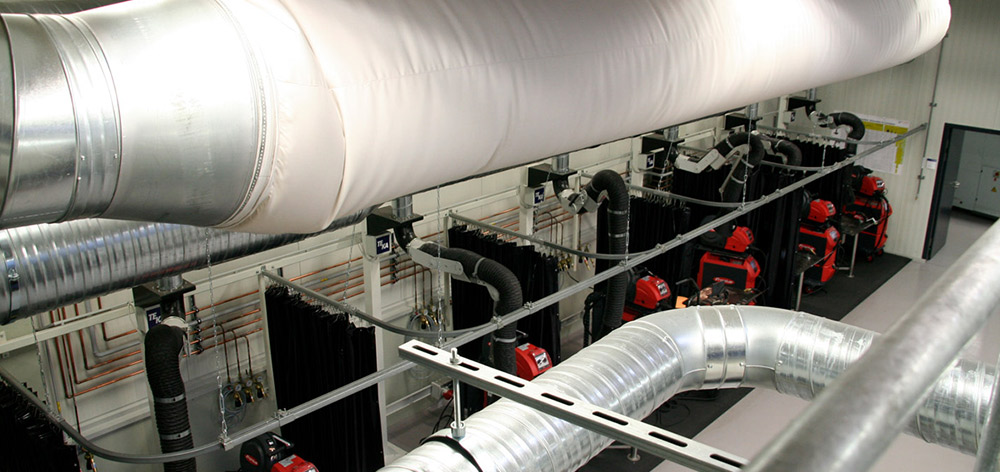

On site, extraction hoods and arms collect the contaminated air in the area of the eight training welding stations at the point of origin. The sound-insulated booth equipped with two grinding tables as well as the plasma hand cutting table, which were also supplied by TEKA, are equipped with rear wall exhaust systems. All three work areas are connected to a central piping system that leads the exhaust air to the filter system. In order to extinguish any sparks that may be sucked in in advance, they are led through an upstream spark pre-separator. The recirculated clean air flows back into the room via a textile air outlet at low noise levels. Tailor-made solutions are part of TEKA's everyday business. Since there was very little space available in the working area, the extraction system including the spark pre-separator could be accommodated above the material storage thanks to its modular design.

The advantages at a glance: ZPF

IFA-certified extraction system for welding smoke class "W3

Space-saving installation of extraction system and spark pre-separator outside the working area

Textile air outlet for even and low-noise return of the cleaned air into the hall

Energy-efficient operation thanks to frequency converter

Heat exchanger for constant room climate in winter

Further information:

Information at Tel. +49(0)2541-84841-0 or by e-mail at info@teka.eu